DWXBJ-1 Electrical Conveyor Belt Repair Machine

Details:

Details:

Description

During the running of conveyor, due to certain reasons, such as weight, fall, and equipment malfunction, etc, may lead to the exposure or leaking material. You must repair it immediately, when you use our repair machine, please repair it by vulcanization way on the surface of belt as the transporter stopping.

Performance & Application

DWXBJ-1 Electrical Conveyor Belt Repair Machine is mainly used to repair the small area broken belt and restore the broken core layer. It's repairing a spot or a piece of belt. Its characteristics are: simple structure, light in weight, operate easily and lower the cost relying on the help of cross beam of vulcanizer machine, as it's the same operating method with curing machine.

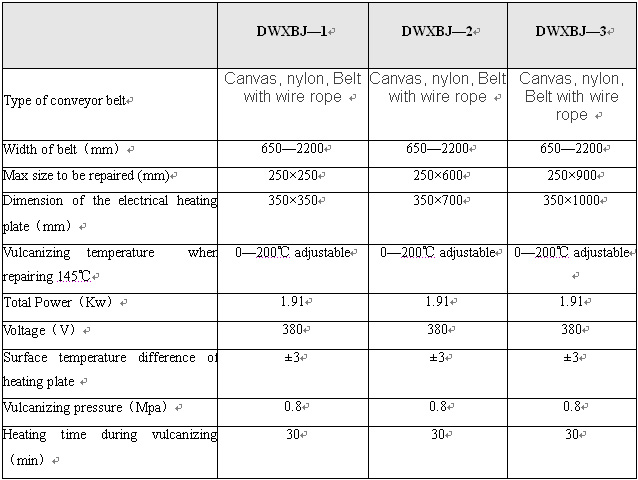

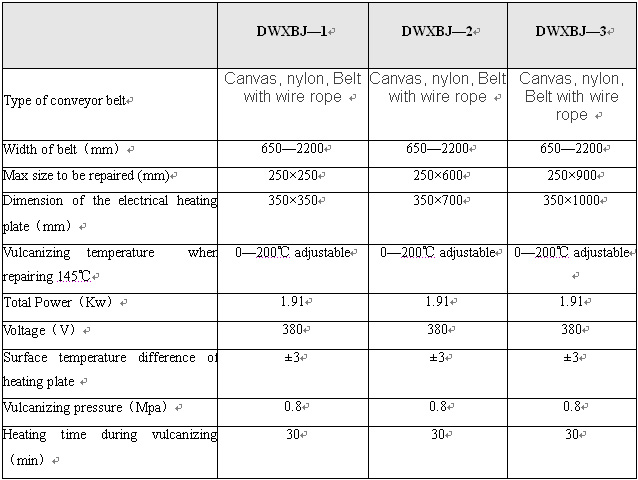

Technical Parameters

Low Voltage Machine:

1. Sulfide Pressure: 0.8Mpa;

2. Temperature: 145 ℃;

3. Rated Power: 2 KW;

4. Repairing maximum belt width: 1,400 mm.

High Voltage Machine:

Installation:

1.Please move the repair machine to the repair location;

2.Please fill the raw rubber to the broken part. (The filling raw rubber part in the vulcanization technics can be taken as reference, or our technical workers demonstrate it as adjusting.)

3. Please put the bottom machine frame rightly aiming at the broken part, meanwhile, put the hydropress plate and the bottom heating plate under the broken part.

4.Please put the top heating plate on the broken part, and lay up the thermal baffle, and then install the machine frame.( ※remark: DWXBJ low voltage series machines are integrative machines.)

5.Install the screw and screw down.

6.Please connect power with electrical control cabinet with primary cable, and separately connect top heating plate with electrical control cabinet, and the bottom heating plate with electrical control cabinet by secondary cable, meanwhile, please separately connect top heating plate and electrical control cabinet, bottom heating plate and electrical control cabinet with temperature-measure components. Please pay attention to the corresponding electrical control cabinet when connecting.

7.Please connect hydropress plate and pressure-test pump with high pressure hoses, and then start the electrical control cabinet, meanwhile, and pump water into the hydropress plate to the condition of vulcanizing pressure.